Metal fabrication is the process of creating metal structures by cutting, bending, and assembling various raw metal materials. Metal fabrication is used to create many of the common items that we use every day, including cars, buildings, and much, much more. Oftentimes, smaller parts for the assembly of larger items are fabricated from metal. For example, the beams and supports used to eventually construct a large commercial building are typically fabricated in smaller sections first, or as individual pieces, and then assembled on-site to create the finished product.

To give another example, and one that is actually a large part of our business- all of the metal balcony railings and metal handrails for a large apartment building development are typically fabricated individually off-site and then transported to the construction site. Once the metal railings reach the job site, they are installed and touched up. This makes the transportation process much easier and more efficient, and helps to ensure that the finish or the actual structure of the product itself isn’t damaged in transportation.

What processes are used in metal fabrication?

There are a wide variety of skills, tools, and processes that are typically used in metal fabrication. It typically depends on the structure, product, or type of metal being fabricated, but there are a few key ones that most manufacturers or metal fabricators will use in almost all projects.

cutting in metal fabrication

Obviously, to create a large structure from much smaller, raw materials, the process almost always requires cutting in one form or another. Raw materials such as sheet metal and metal pipes or tubes are typically freshly-produced and delivered to the fabricator without any modification or further processing. The fabrication shop then has to cut these pieces to the necessary specifications in order to move forward with the metal fabrication process. Cutting can be performed on metal using a variety of machines and tools, including more common types like saws, plasma torches, lasers, and water jets, as well as much more elaborate and high-tech machinery. Some fabrication facilities will even have machinery custom-made to fit their metal cutting needs.

Bending in metal fabrication

Metal typically requires being bent to create a specific form, especially from metal pipes and/or tubes. These tubes are typically very strong, often made out of aluminum or steel, and require a large amount of force to be bent. In order to create a custom metal pipe railing, for example, we almost always have to use a pipe bender machine to create specific angles and shapes from an aluminum or steel tube that is completely straight when it reaches our metal shop.

folding in metal fabrication

When working with sheet metal, especially, fabricators have to “fold” (or bend) it to specific shapes and angles. This is commonly used for the fabrication of cars, and is also often used in architectural metal fabrication and structural metal fabrication, among others. Like bending, folding metal requires a large amount of force or pressure, and often employs the use of large machines, which are typically hydraulic. It’s a precise and sometimes difficult process, and is often avoided using the next fabrication technique.

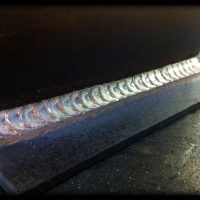

welding in metal fabrication

Again, this is probably one of the most common metal fabrication techniques used. Welding is the process of joining two pieces of metal together by heating the surfaces to a very high temperature, causing them to melt and join together. The pieces are then allowed to cool before being processed further. Welding can be performed on a variety of metals, as well as a variety of shapes and raw forms. There are many different types of welding, but the only ones typically used in our metal fabrication shop are TIG welding, MIG welding, and stick welding. We’ll go into more detail about some different types of welding below.

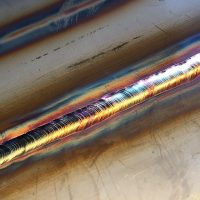

tig welding, gtaw, tungsten inert gas welding, or gas tungsten arc welding

Tungsten inert gas welding (TIG welding) is an arc welding process utilizing a non-consumable tungsten electrode to produce the weld. It originally became very popular in the 1940s for welding both aluminum and magnesium. It utilizes an inert gas shield instead of the then typical slag for protecting the weld pool. TIG welding has led to the popular use of aluminum in architectural and structural applications. We very commonly use TIG welding in our fabrication shop, most often for welding ⅛” aluminum for railings.

MIG welding, GMAW, metal inert gas welding, or gas metal arc welding

Metal inert gas welding (MIG welding) is another arc welding process, this time utilizing a continuous solid wire electrode that is heated and then fed into the weld pool using a welding gun. In order to protect the weld pool from contaminants in the air such as dust or metal filings, the welding gun produces a shielding gas with the electrode. MIG welding became popular around 1949, then used in welding aluminum. This is another type of welding that’s used in our fabrication shop for a variety of projects and materials.

mag welding, GMAW, metal active gas welding, or gas metal arc welding

Metal active gas welding (MAG welding) is yet another arc welding process. It is a very similar process to MIG welding, with the main difference being the type of shielding gas used. MIG welding is typically used on non-ferrous metals such as aluminum, while MAG welding is typically used on ferrous metals such as stainless steel.

stick welding, smaw, covered electrode welding, manual metal arc welding, or shielded metal arc welding

Shielded Metal Arc Welding (Stick welding) is one of the older types of welding used in metal fabrication that we’ll discuss in this article, invented in Russia in 1888. Stick welding is the most widely-used welding process, capable of joining a variety of different metals. A fixed-length electrode is utilized, composed of a solid metal rod at its core, and coated in metal powders and mineral compounds mixed with a binding agent. The core rod conducts the electrical current to the arc as well as provides filler metal for the joint. Stick welders are generally smaller than others, making it a popular choice on construction sites. Our installation and maintenance crews typically utilize stick welding in the field.

FCAW OR FLUX-CORED ARC WELDING

Flux-Cored Arc Welding (FCAW) is another semi-automatic arc welding process, similar to MAG welding. FCAW utilizes a continuously wire-fed electrode, constant voltage, and equipment that is similar to that of MAG welding. It was first developed in the 1950s and served as an alternative to stick welding.

Oxy-Fuel Welding, Oxyacetylene Welding, Oxy Welding, or Gas Welding

Oxy-fuel welding (gas welding) in metal fabrication uses a flame created by the combustion of oxygen and acetylene. There are three flame types, called neutral flame, oxidising flame, and carburizing flame. Neutral flame has an equal ratio of oxygen to acetylene and is generally used for welding. Gas welding equipment is fairly compact and portable, making it a popular choice in many situations. Oxy-fuel welding is commonly used for welding steel. Other types of gas welding can be used for brazing and silver soldering.

PAW or plasma arc welding

There are three operating modes of plasma arc welding: micro plasma, medium current, and keyhole. They are each used on different thicknesses of metals, with micro plasma PAW being used on the thinnest of metals, and keyhole PAW being used on thick metals up to 10mm. Medium current PAW is an alternative to TIG welding, with benefits such as deeper penetration and greater tolerance to surface contaminants. Keyhole PAW is done by increasing welding current and plasma gas flow, and is able to fully penetrate metals, cutting through the surface with the weld pool following behind and forming the weld bead.

EBW or electron beam welding

Electron beam welding (EBW) is a joining process used in metal fabrication where electrons are generated and expelled from an electron gun, then accelerated to high speeds using electrical fields. Magnetic fields are used to tightly focus the electrons, creating kinetic heat, and causing the two surfaces to melt and join together. It’s performed in a vacuum environment, keeping the beam of electrons from scattering, but causing this type of welding to be largely-automated and computer-controlled. It’s typically used for joining materials of different thicknesses, different melting points, etc. Metals that aren’t easily joined, or joined at all, using other, more traditional welding processes are done using electron beam welding.

LBW or laser beam welding

Laser beam welding (LBW) is a welding process used in the fabrication of metal that utilizes a laser beam to join metals together. It’s typically much faster than conventional welding methods, allowing thin materials to be welded much more quickly and thicker metals to be welded with thicker beads. It’s commonly used in the automotive industry, allowing for quick production of parts that is unparalleled by other welding processes. Its automation ability speeds up and increases the accuracy of production even further.

machining in metal fabrication

Machining is the process of trimming and shaping a metal during fabrication using a controlled removal process done by a machine, usually a lathe.

punching in metal fabrication

Punching is a metal fabrication process used for putting holes in a piece of metal. The metal is placed under a die and punched through by a drill.

shearing in metal fabrication

Shearing is the metal fabrication process of performing a long cut on a piece of metal. It’s typically used to trim small portions off the edges of a piece of metal, but can be used for other purposes as well. There are multiple methods of shearing metal depending on need.

stamping in metal fabrication

Stamping is another metal fabrication process that utilizes a die, but stamping is typically used to imprint a piece of metal rather than punch a hole through it. It’s typically used to imprint a design, logo, letters, numbers, serial codes, etc. Metal City Fab uses a custom handheld die with our logo to stamp some of our fabrications.

casting in metal fabrication

Casting is one of the most well-known metal fabrication techniques, where molten metal is poured into a cast to form a specific shape. This can be used to form difficult parts or shapes that would otherwise take much longer and much more work to fabricate using other methods.

grinding in metal fabrication

Grinding is used very extensively by metal fabricators. We use both handheld manual grinders and electrical grinders to smooth edges, smooth welds, and more. It’s most comparable to sanding down a rough edge or surface and is used in pretty much any fabrication shop.

in conclusion

Obviously, this is not a comprehensive list of fabrication techniques, nor is it a full definition of metal fabrication. Techniques and processes vary by fab shop and individual needs, and the actual process of metal fabrication is totally dependent upon what the final product is intended to be. These are, however, some of the most common fabrication techniques, and many of them are used daily in our own fab shop.

No Comments